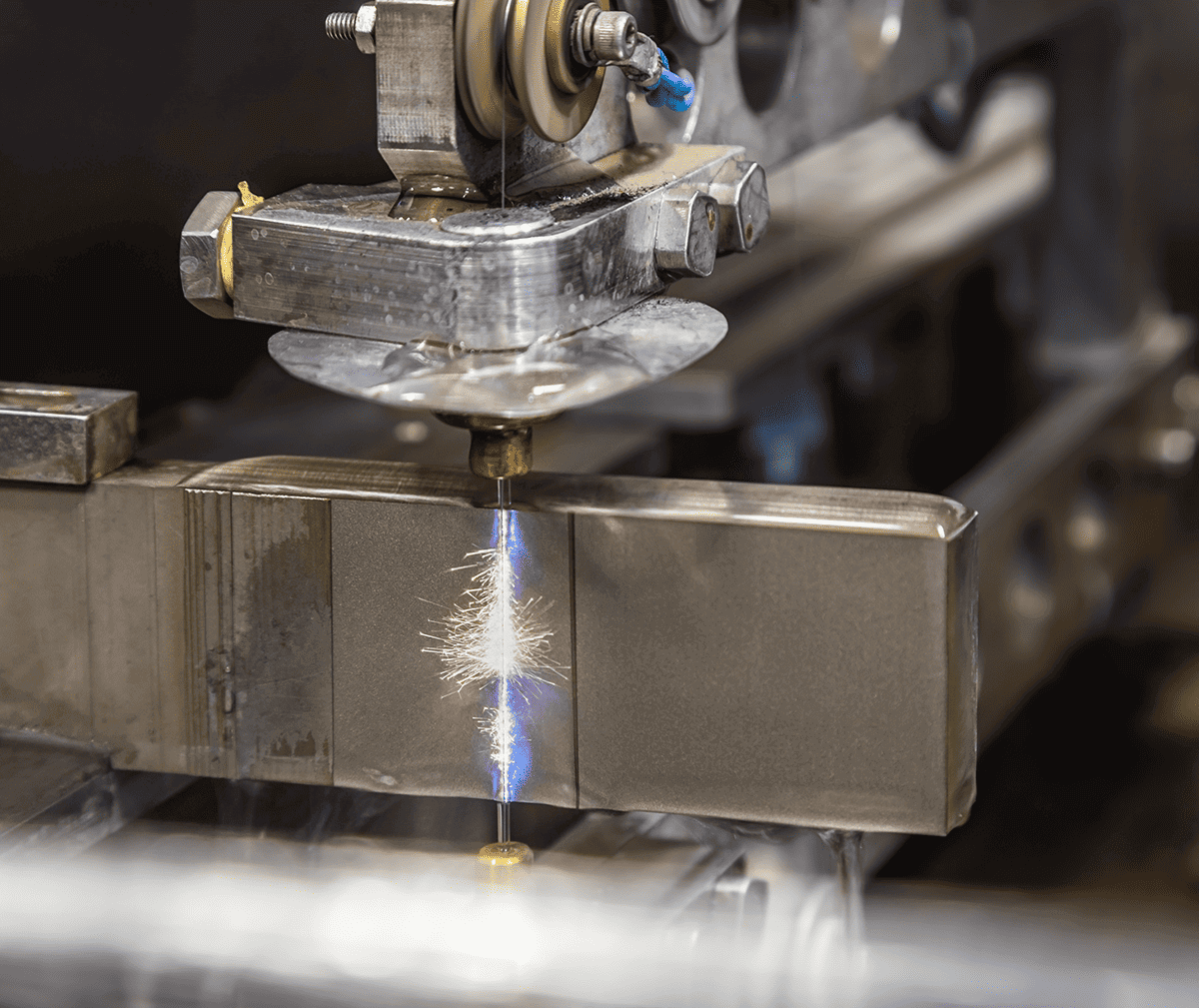

Wire Cutting (Wire Electrical Discharge Machining)

Ultra-precise non-contact metal cutting process using electrical discharge.

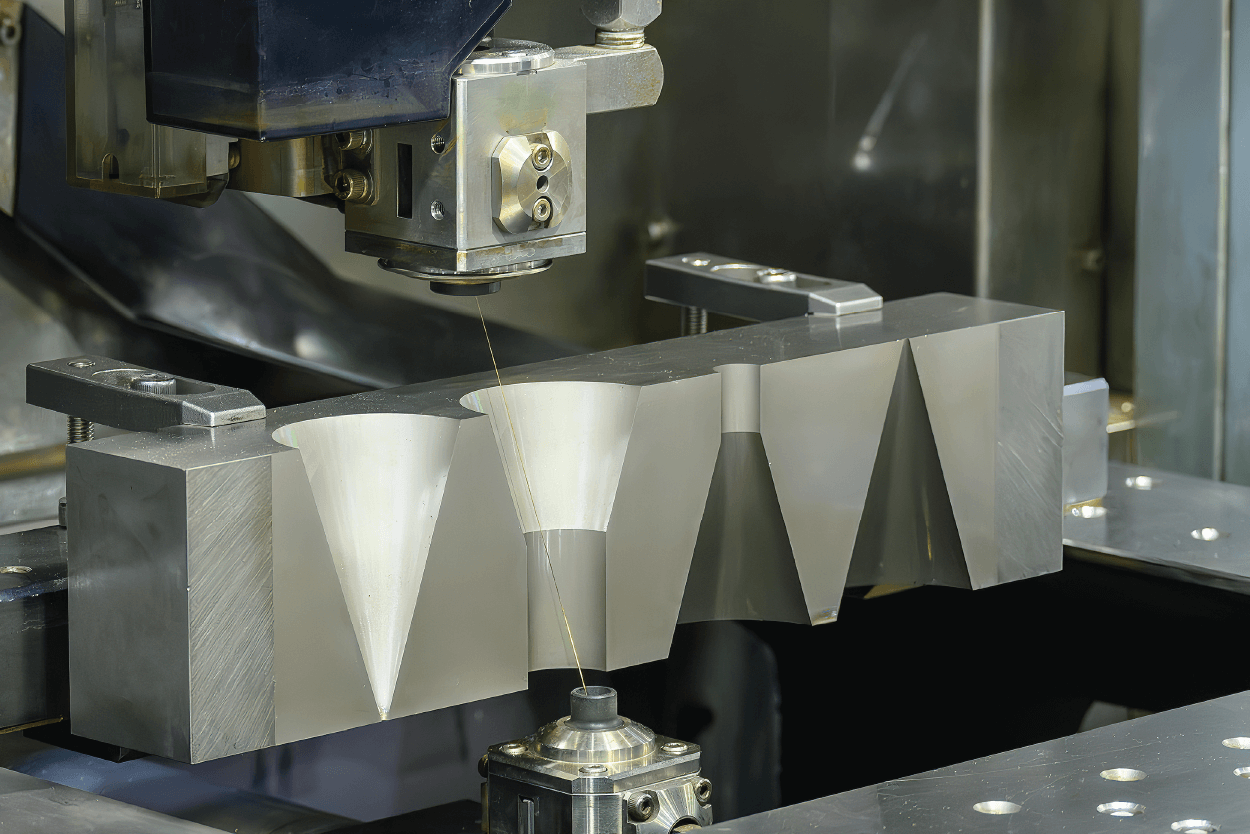

Ideal for hard or heat-treated materials and parts with internal contours, sharp angles, or intricate features.

Does not exert mechanical stress or produce thermal deformation.

Common Uses:

Production of dies, molds, punch inserts, precision slots, gears, and fine details in tooling components.

Technical Advantages:

Tolerances up to ±0.005 mm.

Superior surface finish for tight-fit assemblies.

Cuts electrically conductive materials only (steel, tungsten, copper alloys, etc.).